Worm Gear and Worm Wheel: Precise Speed Reduction Solutions in Mechanical Transmission

In the field of modern mechanical transmission, worm gears and worms, as a type of gear pair capable of transmitting power between perpendicular shafts, have become essential components in industrial applications due to their unique structural and performance advantages. Through the meshing of the worm’s helical teeth with the worm gear’s inclined teeth, they achieve speed reduction, torque increase, and direction conversion, widely used in scenarios such as machine tools, lifting equipment, and automotive steering systems. The following comprehensively analyzes this precise transmission component from aspects including structural principles, core parameters, material selection, and application scenarios.

Structural Principles and Transmission Characteristics

- Large Gear Ratio: High speed reduction ratios (e.g., 30:1) can be achieved in a single stage, with a compact structure;

- Smooth Transmission: Continuous meshing of helical teeth results in low impact and noise;

- Self-Locking Function: When the worm’s lead angle is smaller than the friction angle, reverse rotation is prevented, ensuring safety (e.g., in elevators and cranes).

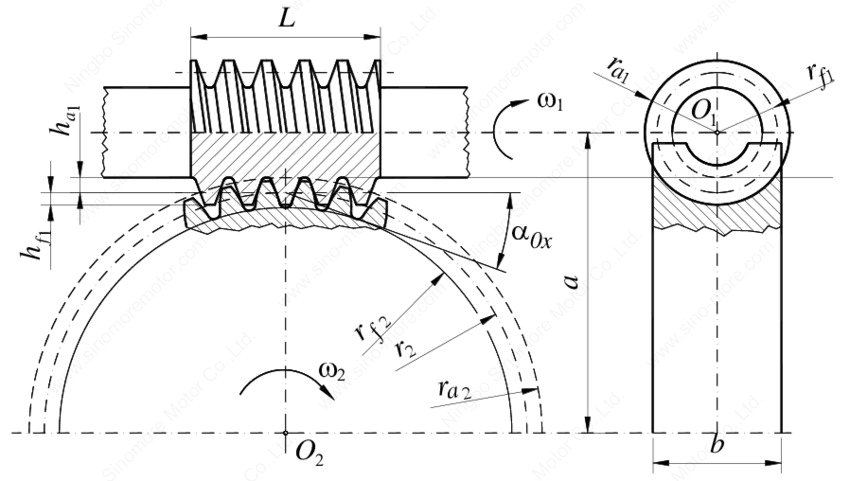

Core Parameters and Design Considerations

- Module and Diametral Pitch

- Module (Metric System): A fundamental parameter measuring tooth size—the larger the module, the bigger the tooth shape and the stronger the load-bearing capacity;

- Diametral Pitch (Imperial System): Refers to the number of teeth per inch of the reference diameter, inversely proportional to the module.

- Pressure Angle

The angle between the line of force during tooth meshing and the tangent to the reference circle, commonly 20° or 14.5° (imperial), directly affecting contact strength and transmission efficiency. - Lead Angle and Number of Starts

- Number of Starts: Equivalent to the number of threads on the worm—single-start worms move the worm gear by one tooth per revolution, while multi-start worms increase transmission speed;

- Lead Angle: Must match the worm gear’s helix angle in both hand (left/right) and degree to ensure smooth meshing.

- Addendum and Dedendum

Radial distances from the reference circle to the tooth tip and tooth root, respectively, determining tooth strength and meshing accuracy. - Backlash

The lateral clearance between non-meshing teeth, which must be controlled within a reasonable range to ensure lubrication and smooth transmission.

Material Selection and Manufacturing Processes

- Worm: Made from high-strength materials like 45 steel or alloy steel, surface-quenched or ground to enhance hardness and wear resistance;

- Worm Gear: Commonly uses soft, wear-resistant materials such as bronze (e.g., tin bronze, aluminum bronze) or engineering plastics (e.g., nylon), reducing friction and prolonging overall service life.

In manufacturing, worm gears are hobbed to create a throat recess that matches the worm’s shape for tight meshing, while worms are precision-machined via turning and grinding to form accurate helical teeth.

Application Scenarios and Advantages

- Industrial Equipment: Speed reduction and torque increase in machine tool feed systems and reducers;

- Transportation: Power transmission in automotive worm steering gears and marine steering engines;

- Precision Instruments: Angle adjustment mechanisms in dividing heads and astronomical telescopes;

- Automation Equipment: Transmission modules in robot joints and lifting platforms.

Their core value lies in achieving high gear ratios with compact structures, adapting to high-precision scenarios through smooth meshing, and ensuring safety via self-locking capabilities.

Sinomore’s Worm Gear and Worm Wheel Solutions

- Diverse Materials: Including bronze worm gears + steel worms, plastic worm gears + stainless steel worms, etc., suitable for different load and environmental requirements;

- Complete Types: Single-start self-locking types, multi-start high-efficiency types, precision micro types, etc., with customization support based on drawings or parameters;

- Leading Processes: Using CNC hobbing and precision grinding to ensure tooth surface accuracy and meshing efficiency, with transmission errors controlled within ±0.01mm;

- Comprehensive Services: Providing full-process support from transmission scheme design and installation debugging to after-sales maintenance, helping customers optimize mechanical system performance.