Products Description

Sintered Bronze Bush Bearing is a high – performance bearing manufactured using powder metallurgy technology. It is mainly made from metal powders such as copper and tin through processes like pressing and sintering. It has a porous structure inside, and these pores are usually impregnated with lubricating oil, giving it unique self – lubricating properties.

Sintered Bronze Bush Bearing is a high – performance bearing manufactured using powder metallurgy technology. It is mainly made from metal powders such as copper and tin through processes like pressing and sintering. It has a porous structure inside, and these pores are usually impregnated with lubricating oil, giving it unique self – lubricating properties.

Self – lubricating Properties

During operation, the lubricating oil in the pores will seep out, forming a lubricating film between the bearing and the shaft, reducing friction. It does not require frequent additional lubrication, which can reduce maintenance costs and downtime. It is suitable for applications where regular maintenance is difficult.

Wear Resistance and Corrosion Resistance

The bronze material endows it with good wear resistance and corrosion resistance. It can withstand long – term friction and harsh working environments, has a long service life, and can operate stably in environments with corrosive substances or in damp conditions.

High Load – carrying Capacity

It has a relatively high load – carrying capacity, which can effectively support and transfer mechanical loads, meeting the operational requirements of various industrial equipment under heavy – load conditions.

Low Noise and Vibration Damping

The self – lubricating properties can effectively reduce operating noise and vibration, providing a stable and quiet operating environment, and improving the overall performance and working comfort of the equipment.

Manufacturing Process

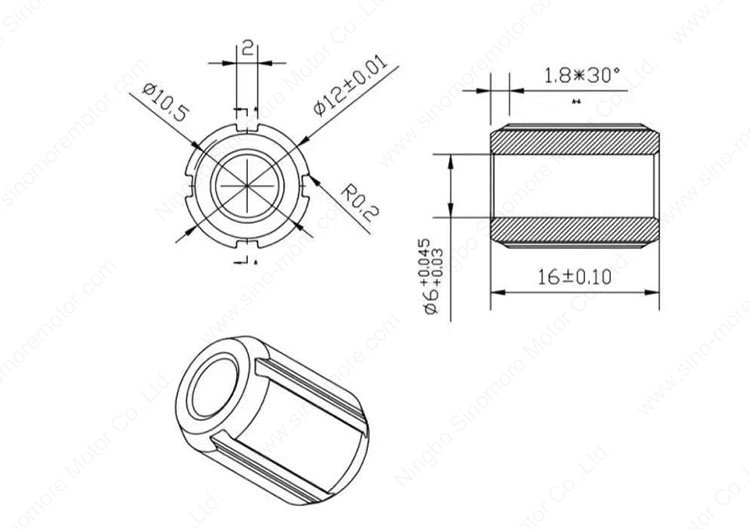

The metal powders are compressed and formed in appropriate molds to give the bearing a specific shape and structure. Then, it is heated to a temperature slightly below the melting point for fusion and bonding to enhance the bearing’s strength. After that, it is machined to the required dimensions. Finally, through methods such as immersion or vacuum impregnation, the lubricating oil is filled into the connected or open pores of the bearing, resulting in a high – precision Sintered Bronze Bush Bearing.

Application Fields

It is widely used in many fields. In industrial machinery, such as machine tools, motors, and pumps, it ensures the stable and efficient operation of the equipment. In the automotive industry, it is used in components such as engines and transmissions, improving the performance and reliability of vehicles. In the field of household appliances, such as washing machines and dryers, it can reduce operating noise and extend the service life. The Sintered Bronze Bush Bearings produced by our company strictly comply with international standards and can be customized according to the drawings and specifications provided by customers to meet the diverse needs of different customers. Whether it is standard – sized products or custom – made parts with special specifications, they can provide reliable support for your equipment with their excellent performance.

Sinomore is focus in the electric motor field, provide PM DC motor, BLDC motor, DC gear motor, universal motor and its CKD & SKD parts, as well as the motor assembly line, rotor assembly line and stator assembly line.

Our team members are full of enthusiasm for electric motor industry, based on more than 20years experience in motor production, we get to know well about this industry and supplying chain in China, we are committed to provide customers with a full package of solution to cost reduction effectively for motor production.

Working with Sinomore, Spend less, Quality better, High flexibility, More from China.

We support the customers who are in the filed of Home Appliances, Automobile, Automation, Power Tools, etc., provide the PMDC motor, BLDC motor, DC gear motor, universal motor, motor assembly line, stator assembly line and rotor assembly line. The motor can be delivered in complete set, SKD or CKD mode.With around 20years working experience in the electric motor field, provide professional consultation. With the enthusiasm for the job, response fast to customer, shorten customer’s communication time.

We provide both of fully automatic motor assembly line and stand-alone motor assembly line, including stator winding line, armature winding line, rotor assembly line, motor assembly line as well as automatic inspection system, cover all the field of household appliances, automobile, electric vehicle, hub motor, power tool, automation control, industrial equipment,etc.

Application scenario

| See also different: | Bush Bearing |