Products Description

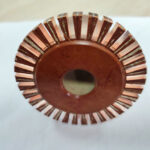

In the microscopic world of motor equipment, there is a crucial component that quietly plays an indispensable role – the commutator. Today, we will focus on our company’s various slotted commutators and explore their outstanding features.

Exquisite Craftsmanship, Laying the Foundation of Quality

Our slotted commutators are meticulously crafted with great attention to detail. Starting from the strict screening of raw materials, high – purity copper is selected as the main material to ensure excellent electrical conductivity, enabling efficient current transmission and reducing energy loss. At the same time, it is paired with high – quality insulating materials, carefully wrapped around the copper, with precise control over the thickness and uniformity of the insulating layer. This safeguards the electrical insulation performance between various components during the motor’s operation, effectively preventing faults such as short – circuits. In the processing stage, advanced CNC equipment is deeply integrated with mature manufacturing techniques. High – precision cutting and forming technologies accurately process the copper into the required slotted structure. The dimensional accuracy of each slot can be controlled within a very small tolerance range, ensuring a perfect fit with other motor components. The surface treatment process further enhances its performance. Through special plating or oxidation treatment, the wear resistance and oxidation resistance of the commutator are enhanced, allowing it to maintain good electrical and mechanical properties during long – term use.

Diverse Slot Types, Meeting Diverse Needs

Our company’s slotted commutators come in a wide variety of types to meet the requirements of different motor application scenarios.

Rectangular – slotted Commutator

The rectangular – slot design is simple and practical. The regular slot shape facilitates the embedding and fixing of windings. In some DC motors that require high rotational speed stability, such as small servo motors, the rectangular – slotted commutator can provide stable support for the windings, making the current commutation process smoother. This ensures that the motor outputs a stable torque, enabling precise position and speed control.

Trapezoidal – slotted Commutator

The unique structure of the trapezoidal – slotted commutator gives it better adaptability to windings. Its gradually widening slot design can better accommodate more turns of wire during winding, making it suitable for motors that require high – power output, such as power tool motors. Under the working conditions of frequent start – stop and high – load operation of power tools, the trapezoidal – slotted commutator can withstand large current surges, reduce winding heating and wear, and extend the service life of the motor.

Arc – slotted Commutator

The arc – slotted commutator is tailor – made for motors that pursue extremely low – noise operation. Its arc – shaped slots can effectively reduce the friction and collision noise between the windings and the commutator. In noise – sensitive application scenarios, such as motors in smart home devices, the arc – slotted commutator can make the motor run more quietly, creating a comfortable environment for users.

Wide Application, Empowering Industrial Development

Various slotted commutators are widely used in multiple fields. In the field of industrial automation, whether it is the servo motors in automated production lines or the drive motors of various precision instruments, our commutators can help them operate accurately, ensuring the efficiency and stability of the production process. In the field of consumer electronics, from electric shavers to handheld massagers and other small appliances, the commutators ensure the stable operation of products with their reliable performance. In the transportation field, our commutators are also used in the motors of electric bicycles and electric vehicles, providing solid power support for green travel.

With exquisite craftsmanship, diverse types, and wide applications, our company’s various slotted commutators have already become a reliable guarantee for the efficient and stable operation of motor equipment. In the future, we will continue to innovate and constantly improve the performance and quality of commutators to contribute to the development of more industries.

Sinomore is focus in the electric motor field, provide PM DC motor, BLDC motor, DC gear motor, universal motor and its CKD & SKD parts, as well as the motor assembly line, rotor assembly line and stator assembly line.

Our team members are full of enthusiasm for electric motor industry, based on more than 20years experience in motor production, we get to know well about this industry and supplying chain in China, we are committed to provide customers with a full package of solution to cost reduction effectively for motor production.

Working with Sinomore, Spend less, Quality better, High flexibility, More from China.

We support the customers who are in the filed of Home Appliances, Automobile, Automation, Power Tools, etc., provide the PMDC motor, BLDC motor, DC gear motor, universal motor, motor assembly line, stator assembly line and rotor assembly line. The motor can be delivered in complete set, SKD or CKD mode.With around 20years working experience in the electric motor field, provide professional consultation. With the enthusiasm for the job, response fast to customer, shorten customer’s communication time.

We provide both of fully automatic motor assembly line and stand-alone motor assembly line, including stator winding line, armature winding line, rotor assembly line, motor assembly line as well as automatic inspection system, cover all the field of household appliances, automobile, electric vehicle, hub motor, power tool, automation control, industrial equipment,etc.

Application scenario

| See also different: | Commutator |